Monday 10th March 2025

Chain lever hoists are in wide use throughout industry for both lifting and pulling applications. They provide a comparatively lightweight method of moving loads over a short distance and the lever operation allows them to be used in any operating position.

This ability to operate in any attitude makes the chain lever hoist a very versatile tool particularly in rigging applications where it may be used as an adjustable sling leg to enable a load to be balanced or for line adjustment when positioning a load or as a means of restraint to quote just three examples.

Most modern chain lever hoists have a ‘free wheel’ facility, which allows the operative to rapidly extend or take up slack chain under no load conditions.

Two basic types are available, one employing fine tolerance (calibrated) steel short link chain, the other employing roller chain. Some manufacturers offer both types and in addition there may also be a choice between a lightweight aluminium alloy model and a ferrous model.

Most modern chain lever hoists have a ‘free wheel’ facility, which allows the operative to rapidly extend or take up slack chain under no load conditions.

Two basic types are available, one employing fine tolerance (calibrated) steel short link chain, the other employing roller chain. Some manufacturers offer both types and in addition there may also be a choice between a lightweight aluminium alloy model and a ferrous model.

4.1 SCOPE

4.1.1

This section of the code covers the use of hand operated chain lever hoists where the hoisting effort is applied by means of a built-in lever

4.1.1

This section of the code covers the use of hand operated chain lever hoists where the hoisting effort is applied by means of a built-in lever

4.1.2

The information contained applies to both the fine tolerance (calibrated) link chain model and the roller chain model unless otherwise stated.

The information contained applies to both the fine tolerance (calibrated) link chain model and the roller chain model unless otherwise stated.

4.2 DEFINITIONS

In addition to definitions given in section 1 subsection 1.2 of this code, the following should be noted:

In addition to definitions given in section 1 subsection 1.2 of this code, the following should be noted:

4.2.1 Drawn Up Dimension

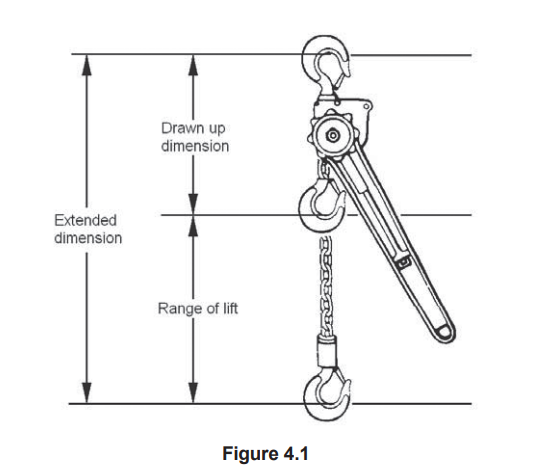

The drawn-up dimension is the distance between the top and bottom hook saddles when the bottom hook is in the fully raised position. (See figure 4.1)

4.2.2 Range of Lift

The range of lift is the distance which the hook attached to the load chain travels between the extended and the drawn-up positions. (See figure 4.1)

4.2.3 Extended Dimension

The extended dimension is the distance between the hook saddles when the bottom hook is in the fully extended position. It equals the sum of the drawn-up dimension and the range of lift. (See figure 4.1)

The extended dimension is the distance between the hook saddles when the bottom hook is in the fully extended position. It equals the sum of the drawn-up dimension and the range of lift. (See figure 4.1)

4.2.4 Effort

The effort is the force on the lever required to lift a specified load. The specified load is usually the rated capacity of the hoist.

4.3 TYPES OF HAND OPERATED CHAIN LEVER HOISTS

A number of different makes are currently available and some manufacturers produce more than one model. The following information, although of a general nature, gives guidance on the main options.

4.3.1 Type of Chain

The chain lever hoist will be designed to employ one of two types of chain, fine tolerance (calibrated) round steel short link chain or roller chain. (See figure 4.2)

4.3.2 Material of Manufacture

The standards for chain lever hoists permit manufacturers to use a wide range of materials provided that they possess the necessary strength and physical properties.

In practice, the choice available to the user is limited to the materials from which the hoist body and lever are manufactured. Some models employ light alloys whilst others are all ferrous.

The standards for chain lever hoists permit manufacturers to use a wide range of materials provided that they possess the necessary strength and physical properties.

In practice, the choice available to the user is limited to the materials from which the hoist body and lever are manufactured. Some models employ light alloys whilst others are all ferrous.

4.3.3 Number of Falls

In general, there is no choice available to the user in this respect. The lower capacity models lift the load on a single fall of load chain, the higher capacity models utilising two or more falls. (See figure 4.2)

4.4 PRINCIPLES FOR THE SELECTION OF CHAIN LEVER HOISTS

4.4.1 Application of Machines

Hand operated chain lever hoists are suitable for a variety of purposes and the braking mechanism is designed for use at any attitude, making them suitable for both lifting and pulling applications.

4.4.2 SWL

Under normal operating conditions, i.e. where there are no hazardous conditions the SWL will be the same as the rated capacity. Due allowance should be made in those cases where the load is not accurately known.

4.4.3 Brake Mechanism

The hoist should be fitted with an automatic brake capable of arresting and sustaining the load. If it is intended to lift a load which is very light, i.e. 10% or less, in relation to the lever hoist’s rated capacity, the manufacturer’s or supplier’s advice should be sought with regard to the performance of the brake. This is because the brake relies upon the hoisting effort for its operation and with a very light load the effort available may be inadequate to operate the brake fully.

4.4.4 Type of Chain

For the majority of applications, there is little to choose between the link chain and roller chain models. It should be noted however that roller chain will only articulate in one plane otherwise such factors as price, weight or drawn up dimension may influence choice of one over the other

4.4.5 Chain Retention

The standards to which some older models were made required a stop on the free end of the chain. Most modern standards now also require the free end of the chain to be fitted with a chain end stop to prevent the chain passing completely through. This stop must be able to withstand 2.5 times the tension in the chain when the rated capacity is being lifted. This requirement is an important safety feature and should be considered as the minimum for hoists of all ages. If the user inadvertently runs the chain fully out and the slack end anchorage is not adequate, the chain will easily continue through the hoist and drop the load.

The standards to which some older models were made required a stop on the free end of the chain. Most modern standards now also require the free end of the chain to be fitted with a chain end stop to prevent the chain passing completely through. This stop must be able to withstand 2.5 times the tension in the chain when the rated capacity is being lifted. This requirement is an important safety feature and should be considered as the minimum for hoists of all ages. If the user inadvertently runs the chain fully out and the slack end anchorage is not adequate, the chain will easily continue through the hoist and drop the load.

4.4.6 Material of Manufacture

Hoists employing light alloys or steel pressings for the body and/or operating lever offer a significant saving in weight over those using castings and this adds to their value as a portable tool. It should be recognised however that certain alloys may create a spark in contact with steel and should not therefore be used in explosive or potentially explosive atmospheres, e.g. mining.

4.4.7 General

In addition to the above, consideration should also be given to the following when selecting hand operated lever hoists:

(1) The documentation required by legislation If this is not on record refer the hoist to a Competent Person for thorough examination.

(2) Length of load chain required.

Note:

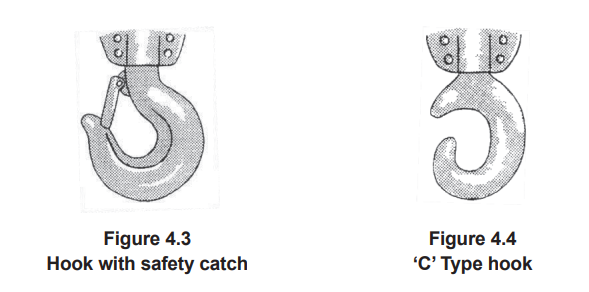

Hooks and other similar devices provided for lifting should be of a type that reduces the risk of the load becoming displaced from the hook or other devices.

This requirement can be met by the use of hooks with safety catches or by the use of ‘C’ hooks. (See figures 4.3 and 4.4)

4.5 INFORMATION WHICH SHOULD BE EXCHANGED BETWEEN THE USER AND THE DESIGNER OR SUPPLIER

As chain lever hoists are frequently used for miscellaneous lifting purposes, precise details of the load to be lifted are not always available. In these circumstances, only a general specification can be given and this should include the following information:

As chain lever hoists are frequently used for miscellaneous lifting purposes, precise details of the load to be lifted are not always available. In these circumstances, only a general specification can be given and this should include the following information:

(1) Intended application e.g. lifting, tensioning or pulling.

(2) The maximum load to be lifted or SWL

(3) Details of the application that may have a bearing on the load to be lifted, e.g. wind, hoisting out of water, etc.

(4) The maximum extended dimension.

(5) The maximum acceptable drawn up dimension if headroom is important.

(6) The range of lift.

(7) The type of chain required.

(8) The conditions of service and in particular any conditions which the user suspects might be hazardous,

e.g. extremes of temperature, high probability of shock loading, uncertainty of weight of load.

4.6 LEGAL REQUIREMENTS

Particular attention is drawn to section 1 subsection 1.3 of this code.

4.6.1

The definition of lifting equipment and accessories used in this code make it clear that hand operated chain lever hoists are lifting equipment. Unless a written scheme of examination (refer to LEEA 032 Guidance to written schemes of examination for guidance), drawn up by a Competent Person, is in place and operating they must be thoroughly examined by a Competent Person at intervals not exceeding 12 months. Reports of thorough examination should be retained and cross referenced to the hoist’s historical records for inspection by the Competent Person or local enforcing authority.

For some applications it may also be necessary to have the installation thoroughly examined by a Competent Person before the hoist is put into service. (See subsection 4.7)

4.6.2

Following repair, hand operated chain lever hoists must be re-verified by a Competent Person. The record of the repair and report of the verification should be retained and cross referenced to the hoist’s historical records for inspection by the Competent Person or local enforcing authority.

Following repair, hand operated chain lever hoists must be re-verified by a Competent Person. The record of the repair and report of the verification should be retained and cross referenced to the hoist’s historical records for inspection by the Competent Person or local enforcing authority.

4.6.3

New chain lever hoists should be supplied with comprehensive information for use. Although the method of operation is very simple and similar for all makes and models, the information should include any limitations peculiar to the particular make and model such as operational temperature range, minimum loading and other

conditions. Such information should therefore be retained for future reference.

New chain lever hoists should be supplied with comprehensive information for use. Although the method of operation is very simple and similar for all makes and models, the information should include any limitations peculiar to the particular make and model such as operational temperature range, minimum loading and other

conditions. Such information should therefore be retained for future reference.

Note:

Although not required by legislation, new lever hoists may be issued with a manufacturer’s certificate in addition to, although possibly combined with, the documents require by the applicable national legislation, if any, i.e. EC Declaration of Conformity required European legislation. This document forms an important part of the record of the hoist. It should be retained and cross referenced to the hoist’s records for inspection by the Competent Person or local enforcing authority.

4.7 INSTALLATION AND COMMISSIONING

4.7.1 The Erection of the Equipment

The erection procedure should be carried out in accordance with the manufacturer’s instructions paying particular attention to the following:

4.7.1 The Erection of the Equipment

The erection procedure should be carried out in accordance with the manufacturer’s instructions paying particular attention to the following:

(1) It is essential to ensure that the structure from which a lever hoist is suspended is adequate for the load it is intended to carry. This load includes the weight of the lever hoist itself together with any attachments and suspension points, i.e. slings, shackles, trolley, etc. plus a 10% additional allowance on the total to take account of the effects of dynamic loading. (See section 1 - appendix 1.4) Where a travelling trolley is employed, it is essential that the runway beam, jib arm, etc. is sufficiently level at all loads (up to the maximum for which it is designed) such that the trolley, hoist, etc. will not run away under gravity.

(2) The top hook should be attached to its support in such a manner that the support fits freely into the saddle of the hook and does not exert any side thrust upon the point. The top hook should be fitted with a safety catch to prevent accidental displacement.

(3) After erection, a check should be made to ensure that the load chain hangs freely and is not twisted or knotted. In particular, special care should be taken with multi-fall lever hoists to ensure that the bottom block has not been turned over between the falls of chain imparting a twist to the load chain. If this has occurred, the bottom block should be carefully turned back until the twist is removed.

(4) The length of the load chain should be checked to ensure that the bottom hook will reach the lowest point required without running the load chain fully out. If the load chain is permitted to run fully out, an undue stress may be placed on the slack end load chain stop/anchorage.

(5) The lever hoist should not be modified in any way, e.g. the load chain should not be lengthened beyond its designed limit and the length of the operating lever should not be increased, without guidance from theCompetent Person in consultation with the manufacturer.

4.7.2 Installation Pre-use Inspection/Thorough Examination

The degree of pre-use inspection or thorough examination required will to some degree depend on the installation conditions. Hand operated chain lever hoists are commonly used as a portable tool for temporary installations in order to effect a limited lifting or moving operation, e.g. in maintenance and plant installation applications. They are designed and intended for the user to erect onto a suitable suspension point or trolley for use in such applications. It is therefore the user’s responsibility to ensure the adequacy and suitability of such suspension arrangements. It will usually be sufficient for a suitably qualified and experienced person to inspect the installation without the need for thorough examination prior to use to ensure the correct attachment of the hoist, in many cases this may be the user of the equipment. That is providing that the hoist has a current report of thorough examination and the supporting structure has been verified. Occasionally hand operated chain lever hoists may be used in more complex installations which may call for a higher degree of examination to be made by a Competent Person (See subsection 4.6)

The degree of pre-use inspection or thorough examination required will to some degree depend on the installation conditions. Hand operated chain lever hoists are commonly used as a portable tool for temporary installations in order to effect a limited lifting or moving operation, e.g. in maintenance and plant installation applications. They are designed and intended for the user to erect onto a suitable suspension point or trolley for use in such applications. It is therefore the user’s responsibility to ensure the adequacy and suitability of such suspension arrangements. It will usually be sufficient for a suitably qualified and experienced person to inspect the installation without the need for thorough examination prior to use to ensure the correct attachment of the hoist, in many cases this may be the user of the equipment. That is providing that the hoist has a current report of thorough examination and the supporting structure has been verified. Occasionally hand operated chain lever hoists may be used in more complex installations which may call for a higher degree of examination to be made by a Competent Person (See subsection 4.6)

Where the Competent Person deems a proof test is necessary as a part of the thorough examination, the test load applied will be governed by the standard to which the hoist was manufactured and by the requirements for the overall installation, e.g. runway, which form a part of the thorough examination and which may differ from those of the hoist. The proof load for hand operated chain lever hoists will usually be 150% of the working load limit, unless the standard to which the hoist was manufactured states otherwise. (Note some standards only require a dynamic test of 1.1 times the rated capacity) Functional testing at the rated capacity and a light load test to ensure the integrity of the brake may also form a part of the examination. Test loads should be applied by operating the machine through such a distance as to ensure that all load bearing parts are stressed

at least once.

4.8 MARKING, STORAGE AND HANDLING

4.8.1 Marking

In addition to the requirements of the applicable national legislation the following information should be permanently and legibly marked on a suitable part of the hoist:

(1) Identification mark. (If the manufacturer has not provided a unique serial number then it is the responsibility of the user to add the identification mark to identify the equipment with the inspection and examination

reports).

(2) SWL (if different from the manufacturers rated capacity mark).

(3) The series or type designation.

(4) Size and grade of load chain (in the case of link chain)

(5) Year of manufacture.

(6) Name of manufacturer or supplier.

(4) Size and grade of load chain (in the case of link chain)

(5) Year of manufacture.

(6) Name of manufacturer or supplier.

Note:

Although not required by most standards, it is recommended that the range of lift should be marked on the hoist as this has operational advantages.

4.8.2 Storage and Handling

When not in use, chain lever hoists should be returned to proper storage. It is recommended that chain lever hoists be suspended by their top hooks with the load chain clear of the ground in order to prevent accidental damage. The general requirements are as recommended in section 1 of this code, i.e. the storage area should be dry, free from injurious pollution and extremes of temperature, together with the following:

(1) Equipment which is returned to stores wet and/or dirty should be cleaned and dried. Powerful solvents or cleaning agents should not be used neither should direct heat. Exposed surfaces liable to corrosion should be suitably protected before going into storage.

(2) In the case of multi-fall hoists employing link chain, care should be taken to ensure that the bottom block is not turned over within the falls as this will impart a twist to the load chain.

(3) When a lever hoist has been in storage, it should be checked by a Competent Person to ensure that the brake is operating correctly before it is put back into service.

(4) When handling lever hoists, they should not be dropped or thrown down and when transported the chains and hooks should not be dragged across the floor surface.

(5) When used out of doors for long periods, steps should be taken to protect the hoist from the elements and in particular to prevent the chains from corroding. It must be stressed, however, that chains and other load bearing parts of the hoist should NEVER be subjected to galvanising or plating processes without the EXPRESS APPROVAL of the manufacturer.

4.9 IN-SERVICE INSPECTION AND MAINTENANCE

4.9.1 Pre-Use Inspection

In addition to the thorough examination required under statutory provisions, all chain lever hoists should be visually inspected by a suitably qualified and experienced person prior to use or on a regular basis, taking account of the conditions of service. For hoists in regular use it is good practice to make the inspection at the start of each shift or working day. For hoists used infrequently it should be done before each use on each day of use.

4.9.1 Pre-Use Inspection

In addition to the thorough examination required under statutory provisions, all chain lever hoists should be visually inspected by a suitably qualified and experienced person prior to use or on a regular basis, taking account of the conditions of service. For hoists in regular use it is good practice to make the inspection at the start of each shift or working day. For hoists used infrequently it should be done before each use on each day of use.

It is recommended that a formal system of pre-use inspection is implemented, and a written record kept identifying the date inspected, confirmation that it passed inspection and the name and signature of the person making the inspection. In the event that it does not pass the inspection, there should be a system a procedure

in place to quarantine the hoist to prevent further use of the equipment until the problem has been resolved. The purpose of the pre-use inspection is to test the functionality of the hoist and make a visual check for obvious defects and, if any of the following faults are present, the chain lever hoist should be withdrawn from service and

referred to a Competent Person:

(1) The load chain is worn or damaged. In particular, attention should be given to the wear which occurs on the bearing surfaces inside of the links and to damage in the form of bent, notched, stretched or corroded links. The chain should articulate freely.

(2) Obvious signs of ‘opening out’ of hooks, that is any noticeable increase in the throat opening, or any other form of distortion in the hooks or suspension fittings.

(3) Obvious signs of damage to the load chain stop or the chain anchor which connects the load chain to the lever hoist casing, whichever is applicable.

(4) When operated under load, there is any jumping or any undue effort is required or there is any visible slipping of the brake.

(5) General damage to the lever hoist body, including any gear covers, breaking of overload protection devices, controls or chain guides, and in particular to the operating lever which could indicate a previous overloading.

Notes:

(1) In the case of link chain, the load chain wheel should be checked for debris in the pockets and in the case of roller chain, the space between the rollers and the mating sprocket should be checked for a build up of debris. Any build up of debris will prevent the load chain from seating correctly and should be removed.

(2) In certain circumstances, very rapid wear of link type load chain can develop which is characterised by a rough appearance on mating surfaces inside of the links. If such circumstances are suspected, then the equipment should be withdrawn from service immediately and referred to a Competent Person.

4.9.2 Interim Inspection

In addition to the thorough examination and pre-use inspection some hoist will require an interim inspection(s). the number, frequency and extent of the interim inspections is based on a risk assessment taking into account the possibility of deterioration of components or assemblies due to the specific conditions of use, to ensure that defects are identified and remedied before they become a danger to persons.

The risk assessment must take account of the manufacturer’s literature, hoist duty and actual conditions of use, for example environmental conditions and utilisation that can cause deterioration. The inspection can be restricted to those critical components identified in the risk assessment and therefore they do not have to be as detailed and time consuming as a thorough examination. Typically the inspection will be a more detailed inspection of one or more of the items listed in 4.9.1, but may also cover some or all of the components covered by the thorough examination (refer to the manufacturers literature or LEEA Lifting equipment examiners hand book for guidance to defined scopes of thorough examination including acceptance and rejection criteria).

4.9.3 Maintenance

Routine preventive maintenance should be carried out according to the manufacturer’s instructions in addition to any requirements of the particular site due to the conditions of service. In any event attention should be paid to the following points:

Routine preventive maintenance should be carried out according to the manufacturer’s instructions in addition to any requirements of the particular site due to the conditions of service. In any event attention should be paid to the following points:

(1) Attention should be paid to the lubrication of the load chain. When applying lubricant, care should be taken to ensure that it penetrates between the bearing surfaces on the inside of the links as failure to do so will considerably reduce the service life of the load chain. Under certain conditions, the use of a wet lubricant

may be undesirable because of either;

(a) the risk of contaminating other goods or products or;

(b) dusty atmospheres where dirt is liable to mix with the lubricant and adhere to the chain.

(b) dusty atmospheres where dirt is liable to mix with the lubricant and adhere to the chain.

In these cases, it is possible to use a suitable dry lubricant spray. Details are available from hoist manufacturers or suppliers.

Note:

Caution is required when applying lubricant to any chain hoist as excessive or careless lubrication may lead to lubricant penetrating the brake which can subsequently fail under load.

(2) No person other than a Competent Person or someone under the supervision of a Competent Person should dismantle the hoist or replace the load chain.

4.9.4 Thorough examination

The lever hoist must regularly be thoroughly examined by a Competent Person to check whether it remains safe to use. This is to be done within a maximum period of 12 months unless a written scheme of examination (for guidance refer to LEEA 032 Guidance to Written Schemes of Examination), drawn up by a competent person is in place and operating.

Reports of thorough examination should be compliant with the legal requirements or the LEEA template documents, retained and cross referenced to the hoists historical records for inspection by the Competent Person or the enforcement authority.

Any defects found by the examination should be reported to the owner of the equipment, who must assess the root cause of the defect and implement procedures to prevent reoccurrence, e.g. training of operators, increased inspections, etc., before remedying the equipment and returning it to service.

The competent person may deem it necessary to supplement their examination with testing. Such testing could be NDT, light load testing, functional testing, overload testing, etc. The nature and extent of testing is always at the discretion of the competent person in support of their thorough examination.

Note:

Unless a mandatory requirement of the applicable national legislation or manufacturer, LEEA does not recommend the routine overload testing of lever hoists, except following an exceptional circumstance such as significant modification or repair. This is because overload testing has few benefits and number of disadvantages;

- Some manufacturers do not recommend overload tests, except in ‘exceptional’ circumstances.

- Repeated overloads can cause deterioration of the equipment over time.

- Most structural failures are the result of fatigue and such defects will not be revealed by an overload test;

- fatigue cracking can be identified during thorough examination.

- Defects such as fatigue cracking can be made worse by overload testing but may still not be identified bythe test.

- If equipment fails during testing it could be dangerous and will certainly be expensive

- Inspection bodies do not recommend it as there is no defined structural or mechanical benefit

4.10 SAFE USE OF HAND OPERATED CHAIN LEVER HOISTS

In addition to any specific instructions relating to the safe use of the lever hoist issued by the manufacturer, the following points should be observed:

In addition to any specific instructions relating to the safe use of the lever hoist issued by the manufacturer, the following points should be observed:

(1) The lever hoist must not be used to raise, lower or sustain a load that is in excess of the SWL marked upon the lever hoist.

(2) Do not use the load chain to form a sling i.e. it must not be wrapped around the load and back hooked, snickled or choke hitched. (See figure 4.5) This is because doing so will mean that there is no longer a swivel between the load and the hoist and in addition the forces on the links at the point of snickle may

affect the calibration of the chain.

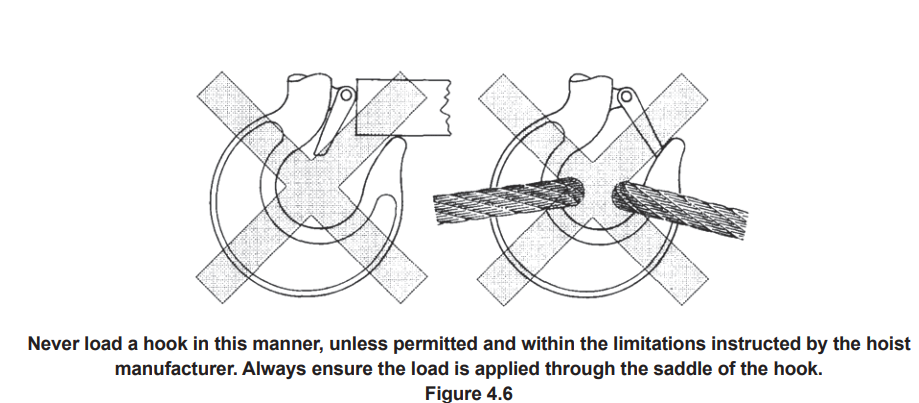

(3) The bottom hook should be attached to the load such that no part of the load is in contact with the point of the hook. (See figure 4.6)

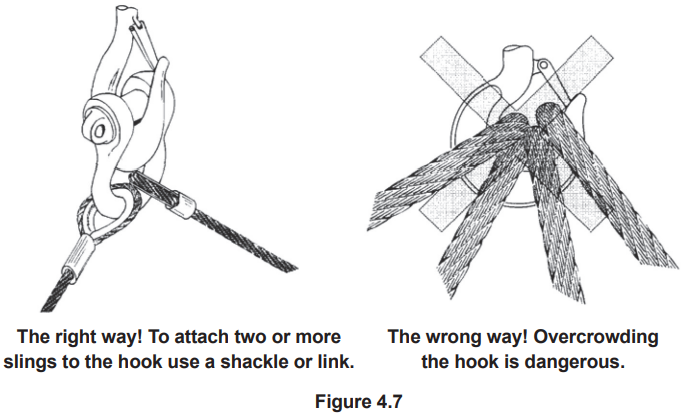

(4) The bottom hook should not be crowded with the terminal fittings of slings. To prevent the hook becoming overcrowded, LEEA recommends that the upper end of the sling legs are connected by means of a shackle or link of adequate strength. (See figure 4.7)

(5) The majority of lever hoists and especially the lower capacity models are designed so that one person will be able to operate the machine up to its SWL. This should be borne in mind as if it is found that more than one person is required, it is probable that either;

(a) the load exceeds the SWL of the appliance or;

(b) the appliance is in need of maintenance or;

(c) a combination of (a) and (b) exists.

Whichever may be the case, an unduly high operating effort requires investigation before the lift proceeds. This is not intended to preclude the use of two persons to operate the lever hoist, which may in certain applications be found advantageous, but is to indicate the degree of operating effort normally required.

(6) Care should be taken to ensure that the lever hoist is not subjected to shock loading.

(7) Lever hoists should not be used in a position where they are liable to be subjected to extremes of temperatures beyond the specified manufacturers temperature limits. For example, above a furnace orsmith’s forge or in severe frost, etc.

(8) Loads should not be left suspended from hoists for any length of time unless absolutely essential and a safe system or work and/or additional safety measures are provided to reduce the risk to an acceptable minimum. Where it is as a result of a breakdown, the operative should ensure that the danger area beneath the load is cordoned off to prevent personnel from being at a risk in the event of a descending load. At no time should the operative permit either himself or other personnel to be beneath or on a suspended load.

(9) When a lever hoist is suspended from a crane, e.g. to facilitate accurate positioning of the load, special precautions should be taken as follows:

(a) For use with power operated cranes the SWL of the lever hoist should be reduced by 15% to allow for the higher dynamic loading.

(b) Before hoisting the load with the crane, a short lift should be made with the lever hoist to ensure that the brake is locked.

(b) Before hoisting the load with the crane, a short lift should be made with the lever hoist to ensure that the brake is locked.

(10) Lever hoists should, when no longer required for use, be returned to proper storage.

(11) Care should be taken not to drop a lever hoist. Any appliance which is accidentally subjected to this treatment should be checked over by a Competent Person before further use.

4.11 TRAINING

In addition to the training requirements specified in section 1, subsection 1.9 of this code, operative training should take into account the manufacturer’s instructions for installation and use and also pay particular attention to the following:

(1) The selection of suitable suspension and attachment points.

(2) In the case of multi-fall link chain hoists, steps to be taken if the bottom block has been turned over in the

falls of chain to remove the twist.